If you are still here, then know that we are rebuilding the double-barrel venturi-type carburetor found on a 1978 AMC 304 V8. First thing before I rebuild a carburetor, I like to make sure that I am well read on the metering circuits of the particular model. This particular carb is rocking out 5 circuits, from low speed idle to quick-response full-on blazing wide-open, super-swamper smokin', mud flingin', beer drinkin', nitro funny car action. Four wheel burnout, followed by a monster wheelie:

I put the carb in a tub and took 360 degree photos of it for assembly reference and before and after kinda pictures. Next I began disassembling and placing the pieces into and organizer. I have found those tackle-box type organizers to be the best when working with carburetors or for anything with a lot of little pieces. I took pictures as new pieces were revealed, both for your entertainment and for my reference. Don't worry, I am sparing you of the over 50 pictures of the carburetor assembly.

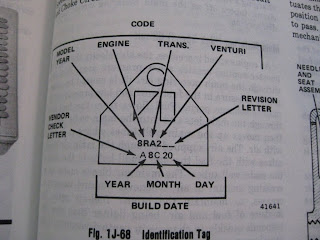

So I took it apart and made some reference measurements as I went along. Fortunately, I have two manuals on how to set it up from scratch, but just for a sanity check.

I was removing the powervalve and snapped off the top threads and lit up a storm of displeasure. Fortunately, later in the day I discovered that in the carburetor rebuild kit that the previous owner included with the jeep contained a new power valve! I got so lucky! I then finished the complete disassembly and then sprayed a gratuitous amount of carburetor cleaner over the carburetor bodies and air horn. During all of that, I must have overlooked taking out the accelerator pump check ball because I later found the weight for the ball, but no ball. Once again, I lucked out super hard because the overhaul kit comes with two balls...har har.

Currently the carburetor main body, air horn, and other miscellaneous covers are in my dishwasher.

I put the ual in manual.

Air screw adjustments:

Auto-choke linkages

Fuel inlet, accelerator pump exterior, and powervalve housing:

Throttle linkages

Choke adjustment

Main body of carburetor:

Parts Tray #2

Air horn and main body:

Parts tray #1

This is the spacer between the intake manifold and the carburetor. It gives spatial clearance for the powervalve and also serves as a heat insulator between the intake manifold and carburetor body. For some reason it was cracked or whatever. I tried to find a new one, but couldn't. Don't trash it, JB weld it!